EFB Pellets

EFB pellets are a sustainable biomass fuel made from the Empty Fruit Bunches, a byproduct of palm oil production. They are created through a process that includes washing, shredding, drying, crushing, pelletizing, cooling, and packing. These pellets are compact, energy-dense, and easy to handle, making them suitable for various heating and energy applications. EFB pellets help in waste management, reduce greenhouse gas emissions, and provide economic benefits by creating additional revenue streams and jobs. They are a key component in the transition towards renewable energy, offering a cleaner and more sustainable alternative to fossil fuels.

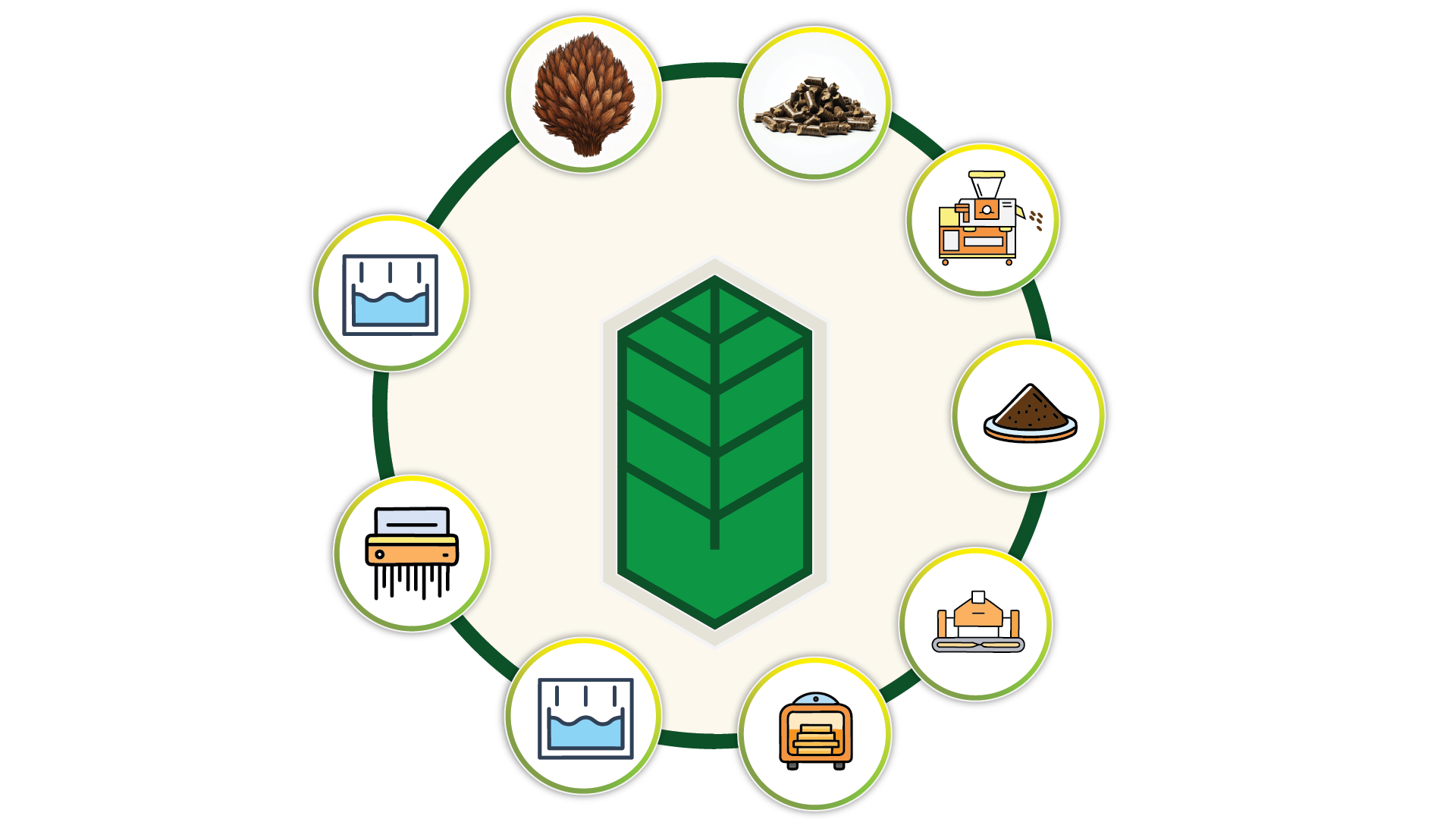

Production Flow

Raw Material

Water Washing Pre-Treatment Process

Shredding System

Washed & Shredded Material

Drying System

Crushing System

Dry & Pulverised Material

Pelletizing System

Finished Product : EFB Pellets

-

01 - Raw Material

The process begins with the collection of EFB, which is the byproduct of palm oil milling. EFB consiste of the fibers that remain after the palm fruits have been removed from their bunches.

-

02 - Water Washing Pre-Treatment Process

The raw EFB is subjected to a washing process to remove the dirt, sand, and other contaminants. This step is crucial for ensuring the quality of the final pellets and for reducing the risk of equipment damage during subsequent processing steps.

-

03 - Shredding System

After washing, the EFB is shredded into small pieces. This is done to reduce the size of the material, making it easier to handle and process in the subsequent steps. Shredding also increases the surface area of the material, which aids in drying and pelletizing.

-

04 - Washed & Shredded Material

The output of the shredding system is more managable forn of EFB, which is now ready for further processing.

-

05 - Drying System

The shredded EFB is then dried to reduce its moisture content below 20%. Drying is essesntial because high moisture levels can negatively affect the quality of the pellets and their combustion efficiency

-

06 - Crushing System

After drying, the material is crushed into smaller particles. This step is also known as pulverizing and is necessary to achieve a uniform particle size (below 5mm) that is suitable for pelletizing.

-

07 - Dry & Pulverised Material

The output of the crushing system is a dry, finely divided material that is now ready for pelletization

-

08 - Pelletizing System

The dry and pulverised EFB is fed into a pelletizing machine, where it is compressed under high pressure to form pellets. The pelletizing process may involve the use of a pellet mill, which can produce pellets of various sizes and densities.

-

09 - Finished Product : EFB Pellets

The pellets that emerge from the pelletizing system are final product. These pellets are dense, uniform in size and have a high energy content, making them suitable for use as a biomass fuel.

Get In Touch

Weng Yat Resources Sdn. Bhd.

Headquarters

Lot 751, Jalan Haji Sirat,

42100 Klang, Selangor, Malaysia

Tronoh Factory

Lot 158458, Jalan Bota,

31750 Tronoh, Perak, Malaysia