Wood Pellets

Wood pellets are a sustainable and efficient form of biomass energy, produced by compressing wood chips, sawdust, or other forms of wood waste into small, cylindrical pellets. These pellets are then used as a fuel source for heating, electricity generation, and even as a feedstock for biorefineries. The production of wood pellets is a way to utilize waste products from the forestry and wood processing industries, reducing environmental impact and providing a renewable energy source.

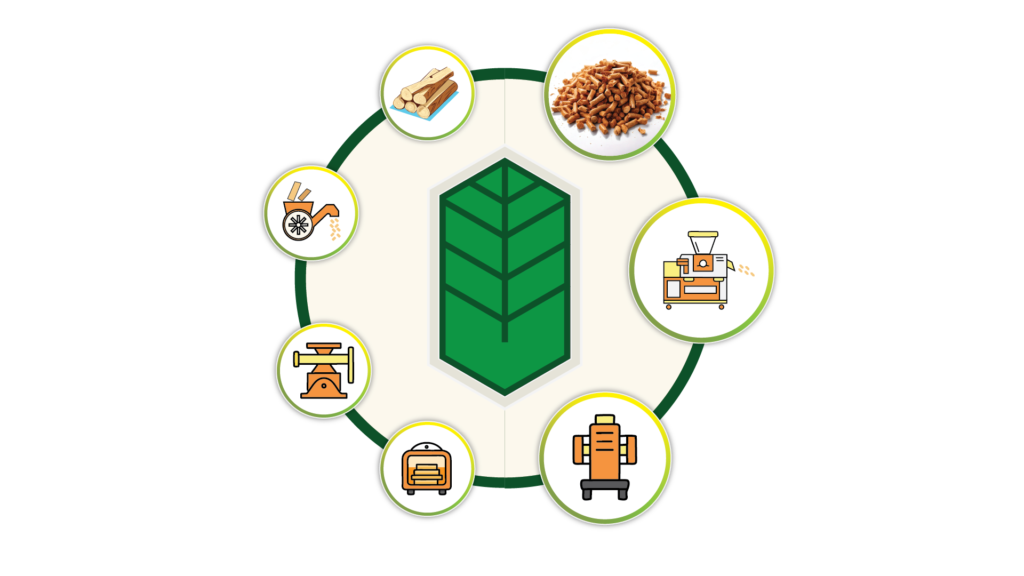

Production Flow

Raw Material

Wood Chipper

1st Hammermill

Dryer

2nd Hammermill

Pelletizer Machine

Finished Product : Wood Pellets

-

01 - Raw Material

The process begins with the selection of raw material. This can include logs, branches, sawdust, and other forestry residues. The quality and type of raw material can affect the final product, so it is carefully chosen to meet specific standards.

-

02 - Wood Chipper

The raw wood material is fed into a wood chipper, which reduces the material into smaller pieces, typically wood chips. This makes the material more manageable and prepares it for further processing.

-

03 - 1st Hammermill

After chipping, the wood chips are sent to the first hammermill. The hammermill is a crucial piece of equipment that grinds the wood chips into a wet sawdust sizes (below 14mm) in preparation for drying.

-

04 - Dryer

The next step is to dry the wet sawdust. Moisture content is a critical factor in the quality of wood pellets, as excess moisture can lead to pellets that are less energy-dense and more prone to degradation. The dryer reduces the moisture content of the dry sawdust to an optimal level, typically between 10% and 15%, ensuring that the pellets will be of high quality and have a long shelf life.

-

05 - 2nd Hammermill

After drying, the dry sawdust are sent to the second hammermill. This step further refines the material, ensuring that it is extremely fine and has a consistent particle size (below 8mm). This consistency is important for the pelletizing process, as it helps to ensure that the pellets will be uniform and have a high density.

-

06 - Pelletizer Machine

The final step in the wood pellet production process is the pelletizer machine. This machine compresses the sawdust under high pressure, forming them into pellets. The heat generated during this compression process helps to bind the sawdust together, creating durable and energy-dense pellets. The pellets are then cooled and can be packaged for distribution.

-

07 - Finished Product : Wood Pellets

The result of this process is the finished product: high-quality wood pellets. These pellets are ready for use in various applications, including heating, electricity generation, and as a feedstock for biorefineries.

Get In Touch

Weng Yat Resources Sdn. Bhd.

Headquarters

Lot 751, Jalan Haji Sirat,

42100 Klang, Selangor, Malaysia

Tronoh Factory

Lot 158458, Jalan Bota,

31750 Tronoh, Perak, Malaysia